10T/H Emulsion bitumen plant for road

Basic Info

Model No.: GYRY10B

Product Description

RY10B Asphalt Emulsion Plant

Model GYRY10B Max Capacitance: 60kWh Power of Mill: 30/22kW Rotation Speed of Mill: 2930rpm Thermal oil Electrical Heating Power: 9kWh Power of Burner: 2.0×105kcal/h Heat Transfer Area: 27m2 Fineness of Emulsified Asphalt: <5μm Productivity: 10-12t/h Weight: 6t Dimension: 6500×2300×2700mm (L×W×H)

Structure & Components

1. Water system: It consists of water boiler, soap tank A, soap tank B, and heat exchanger.

2.Soap Solution System: It consists of soap tanks, solution pump, glass rotameter, electrical regulating valve and manual modulation valve.

3. Acid Supply System

4. Asphalt Supply System: It is consisted of asphalt pump, asphalt hose (heat resistant rubber hose or stainless steel bellow) and asphalt tank.

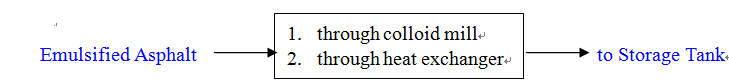

5. Emulsion System: It includes colloid mill, sampling valve and heat exchanger.

6.Heat Exchanging System:This system includes heat exchanger, emulsified asphalt discharging pipeline, water boiler, immersible pump (or sewage pump) and cooling water inlet and outlet.

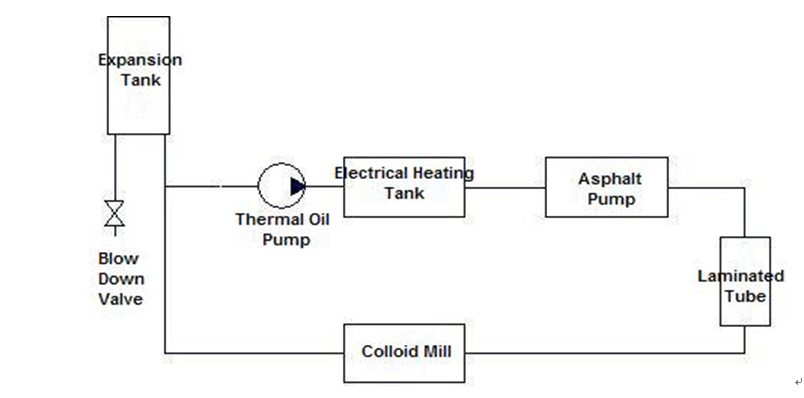

7. Thermal Oil System: This is a closed system. Driven by thermal oil pump, the hear oil flows through electrical heating tank, asphalt pump, laminated tube, mill, and finally the thermal oil pump. In front of the thermal oil pump inlet, an expansion tank for heat oil storage and makeup places above the plant body; blow down valve and the overflow port of expansion tank locate at the bottom of the plant body.

This system applies automatic heat oil temperature control by the electrical heating tank with a thermometer to preheat every pump before working, substituting for gasoline torch heating, which reduces the labors and makes this process easier and faster.

8. Pneumatic Control System: This system takes power from the air compressor and turns the five pneumatic valves on and off by five solenoid valves, which is easy to make and break the water filling and discharging circuits. See the following graph:![NM]YS)1XNX@_RWUOR068)M3 NM]YS)1XNX@_RWUOR068)M3](http://i.glbin.com/product/fc/5d/3c/1d1221da4b69ac864362ecb38f.png)

9. Electrical Control System: It includes two systems: manual control and automatic control. Auto control system automatically controls the liquid level, soap solution flow rate and asphalt content, which performs independently and with no interactions.

Liquid level control: automatic water charging, automatic water discharging by turn, emulsifier and acid charging manually, manual stirring;

Soap solution flow rate control: keep solution flow rate in constancy automatically;

Asphalt content control: automatically keep the asphalt content at setting values.

Also,we have Asphalt Bitumen Distributor Truck,Road Synchronous Chip Sealer,Road Surfacing Maintenance Truck,Asphalt Production Plant,Road Surfacing Maintenance Machine and so on.

Product Categories : Asphalt Production Plant > Emulsion Asphalt Plant